V1 (11/25/2018)

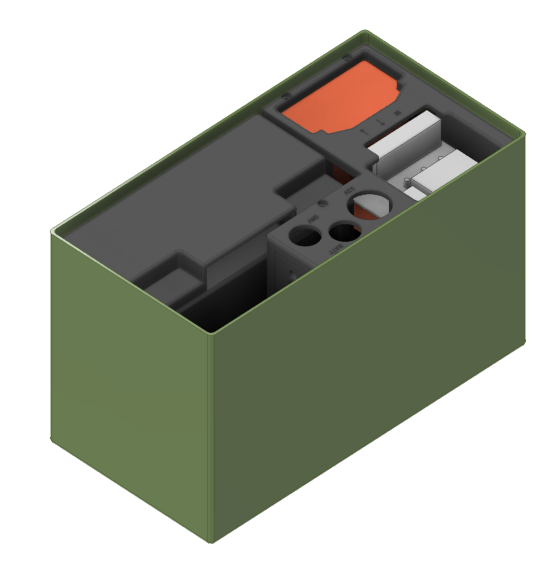

The first iteration of the power supply was inspired by an Ammo can bought at an auction for $5 and a lead acid battery laying around. It was done by combining a 12V lead acid battery, inverter, and a charge monitor.

Parts:

- Ammo Can

- Lead Acid battery (off-the-shelf ATV AGM)

- 300W 12V Inverter

- Charge Monitor

V2 (11/25/2021)

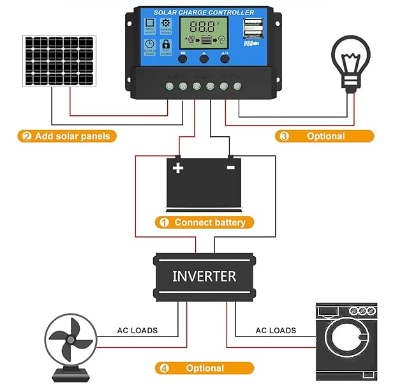

This iteration replaced V1 by swapping out the dead Lead Acid Battery with a new one and swapping the battery monitor with a cheap solar charge controller. This allows me to effectively charge the battery with any sufficient power source.

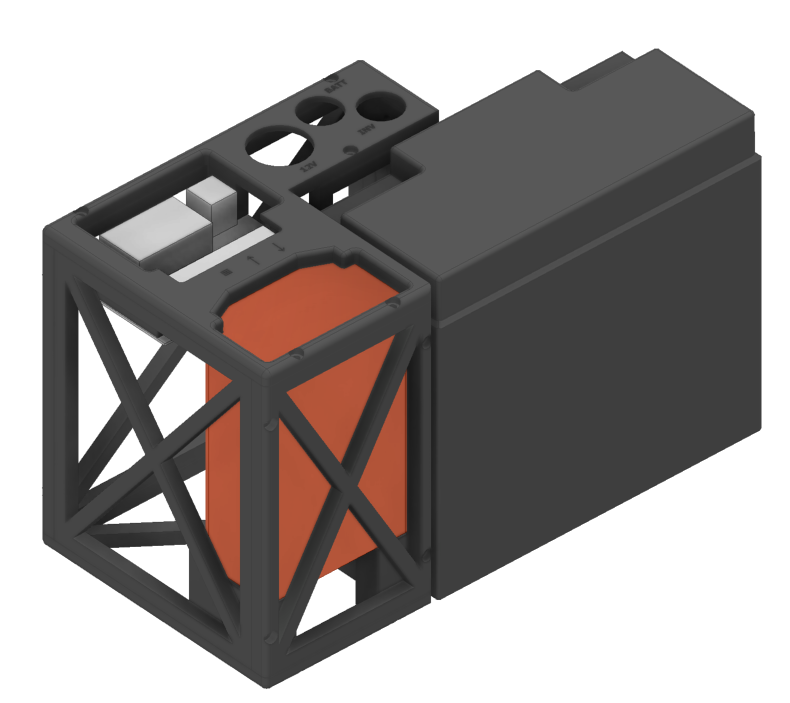

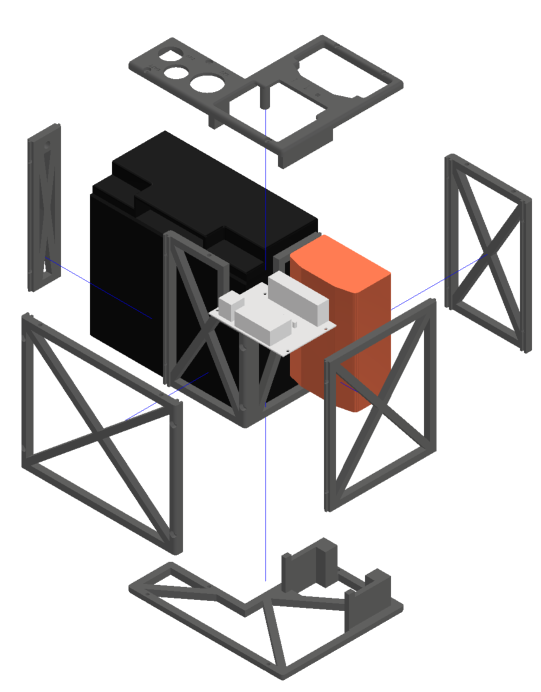

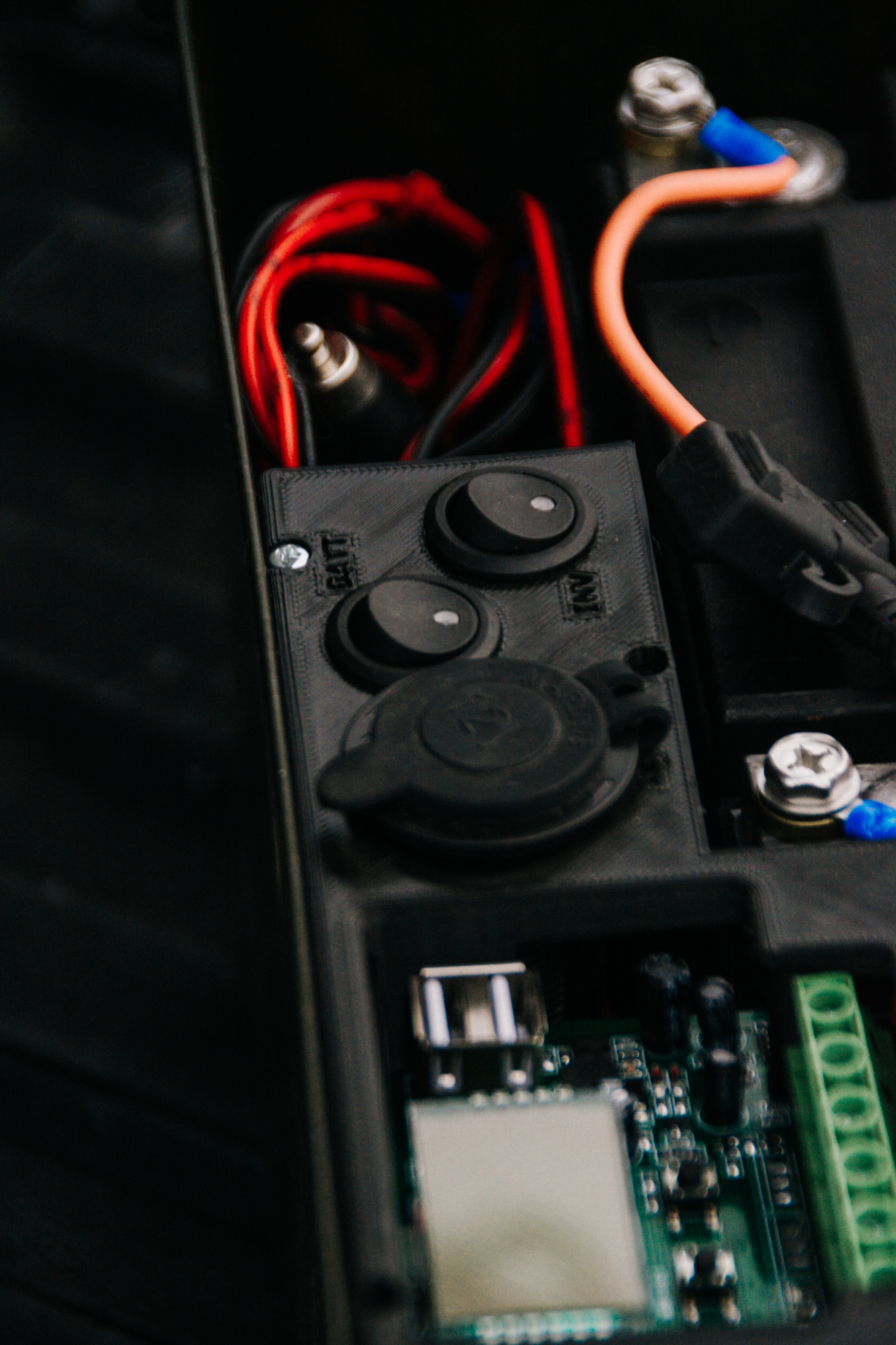

Another major improvement was a 3D printed structure for housing the inverter, controller, battery, and switches. The structure used individual frames that were then screwed together with threaded heat press inserts. All of the 3D printed parts were printed laying down for best lateral strength (across the beams). this means they were printed individually which took a while.

Parts:

- New Lead Acid Battery

- Ammo can from V1

- 12V Solar Charge Controller

- Battery Charger (something like this)

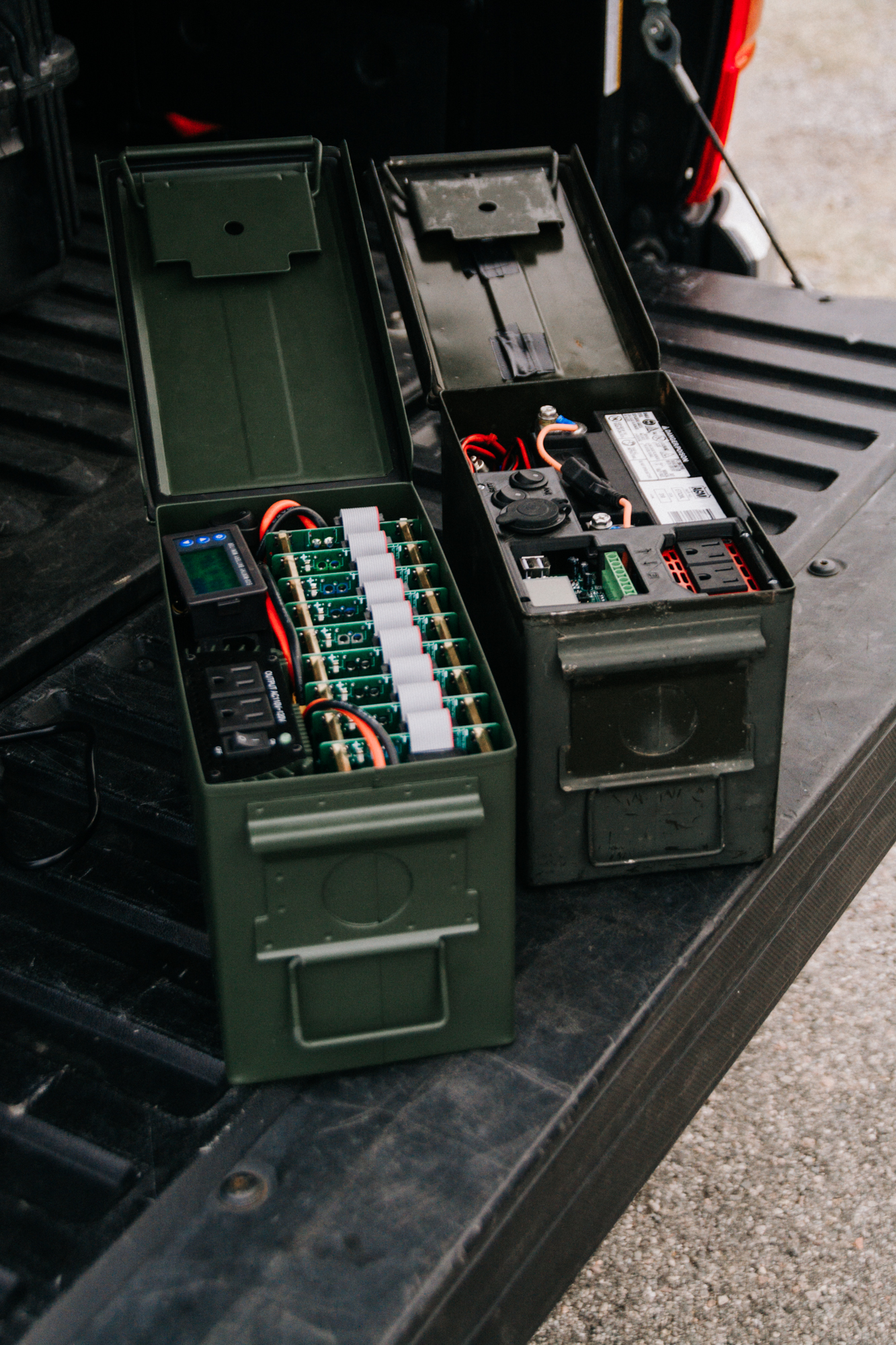

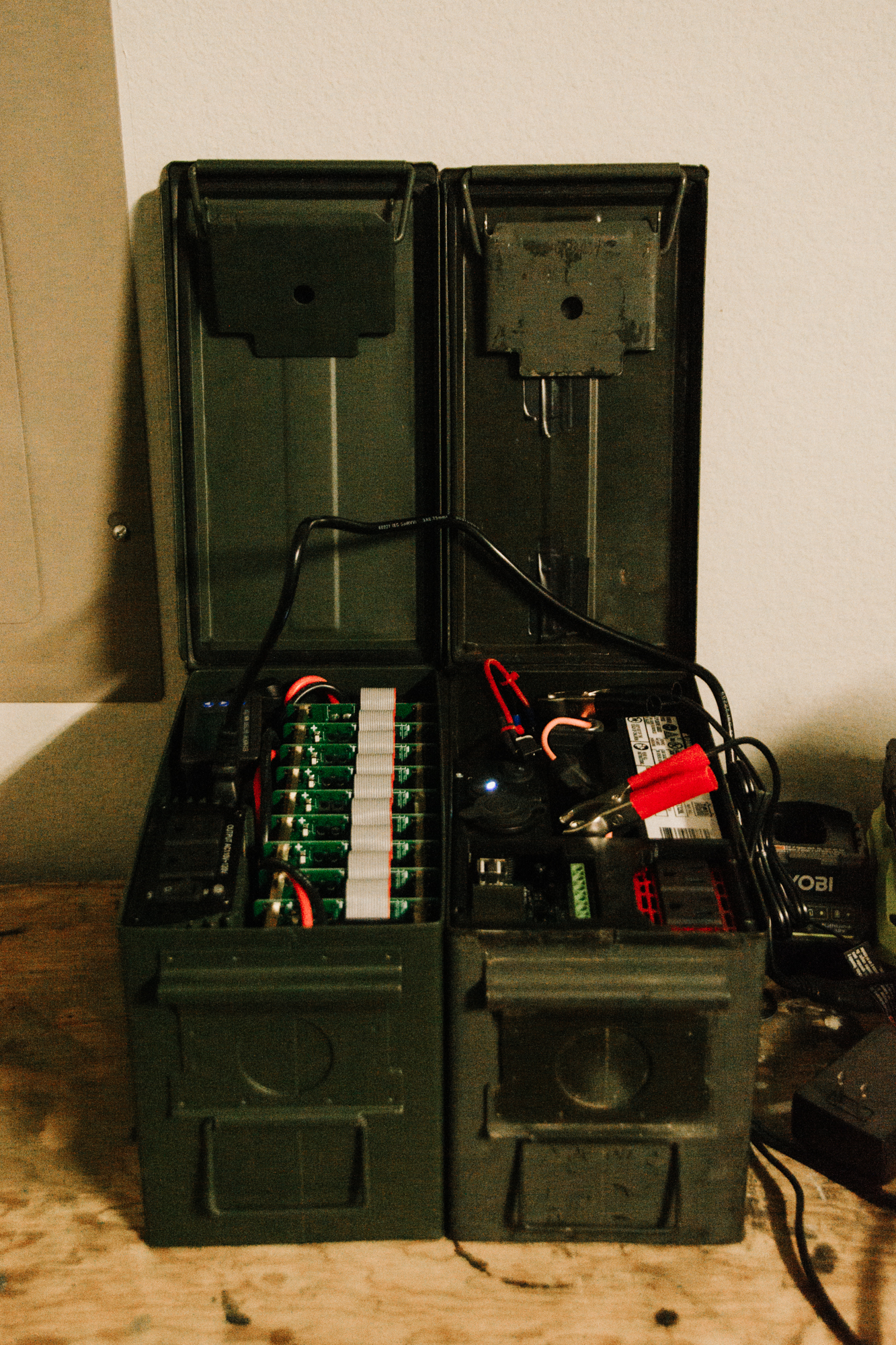

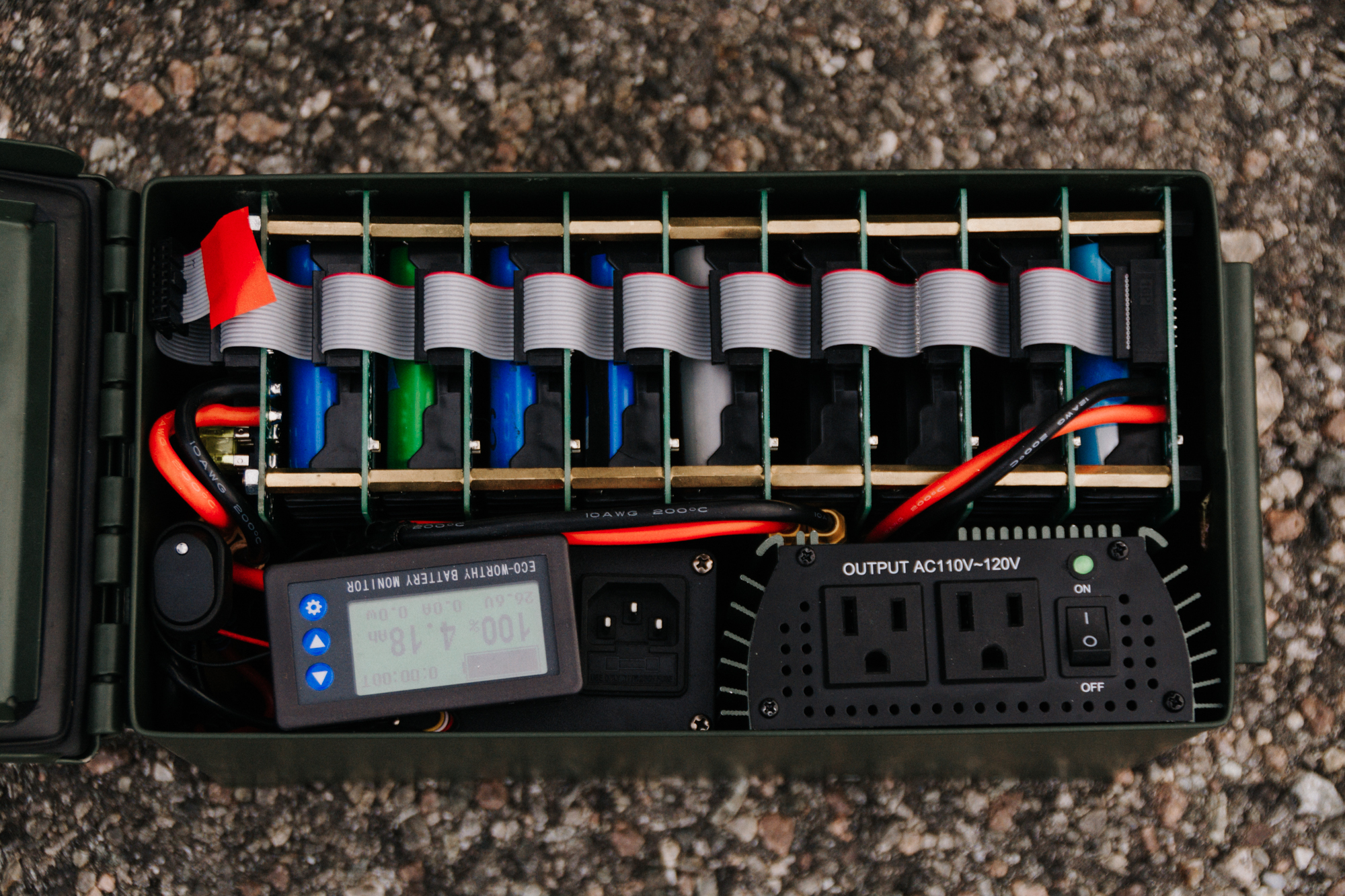

V3 (11/1/2023)

V3 made a drastic change by using a more modern Li-Ion battery chemistry rather than a Lead-Acid. This type of battery has much more power density and more uniform power output thought charge/discharge lifecycle. This results in a lighter battery pack that can push more watthours.

I have been collecting 18650 cells for a while. I usually pull out old laptop batteries from the trash and rip them out. These old laptop batteries are tossed out either because they have become obsolete or no longer function. About 80% of the time, the ones that don't work anymore are due to a single cell being degraded, dragging down the capacity of the entire pack. There are usually 6-8 cells in a pack so this leaves me with several good cells per salvaged pack. Look mom, I'm helping the environment.

Parts:

- Harbor Freight Ammo Can

- 24V Inverter

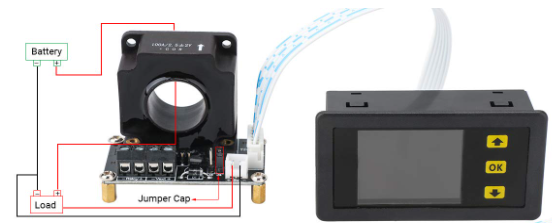

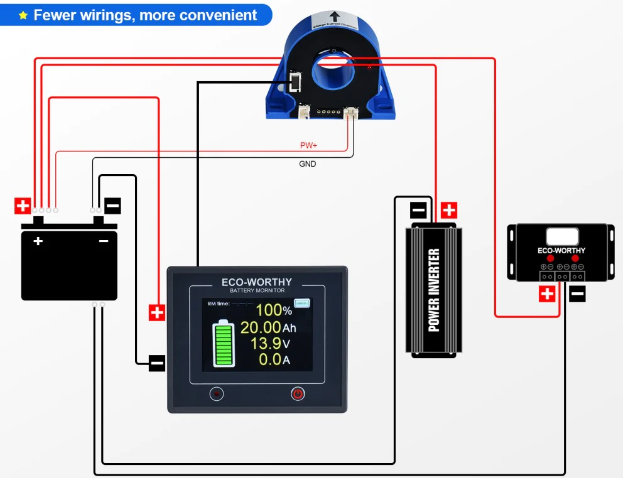

- Eco-Worthy Battery Monitor

- Jehu Garcia 18650 24V 18650 Li-Ion BATTERY MODULE DIY PCB KIT

- 70x 18650 Li-Ion battery cells. (3.6V)

- 29.4V Li-Ion Charger

You have to be careful when installing these batteries though. The Voltage and Capacity need te be matched across each Board and Cell respectively. A board is the 7 18650s that are installed on a PCB. They are wired in series so each cell within a single board need to have the same voltage. If one battery is lower voltage than the others, the board will reach the end-of-discharge point sooner than a normal board. At the same time, each respective 18650 in each board need to have the same capacity in order for the entire module to have full capacity potential. For example, each 2nd 18650 in each board need to have the mAh capacity in order for parallel pack to reach full capacity. See Series and Parallel Configurations for more information.

At some point I would like to 3D print a housing for the pars on this version like I did on V3.

Conclusion

I would like to test the capacity of both of these batteries. I do not have a meter or system to do so yet.

I have notice all of these are done in November, it seems that this is becoming my Fall project. That is probably due to being around the same time I take the most camping trips.